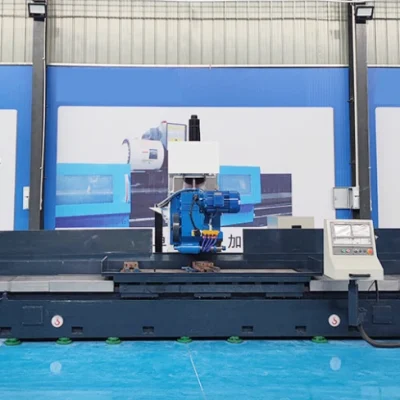

Machine tool introduction

This machine tool is a 1-3 station vertical broaching machine designed and manufactured based on the vertical broaching machine structure, using advanced frequency conversion speed regulation system, soft reversal and small hydraulic impact. Its structural design concept is novel, the appearance is simple, and the unique structural design not only reduces many interlock programs in the electrical aspect, makes the machine tool control system simple and reliable, but also has a reliable broach collision avoidance function, which is a cost-effective high-precision vertical broaching machine, which has been well received by customers for many years.

Product features:

★ The highlight function of this machine tool is that it can remember the position of the used broach, and when used again, there is no need to adjust the limit switch, which avoids the tedious adjustment of the limit step and makes the switching of product specifications more efficient;

★ The guide rail adopts high-precision heavy-duty roller linear guide, fixed with the skateboard by 10-12 sets of sliders, and the length of the slide plate is about 1.5 meters, which has high precision stability;

★ It has automatic tool pick-up and drop-off and broaching escort functions to improve broaching accuracy and reduce the labor intensity of operators.

★ There is a high-pressure chip punching device inside the worktable, which can effectively remove the residual iron filings on the broach and improve work efficiency;

★ It has the function of frequency conversion and speed regulation, the speed adjustment is flexible, the oil temperature is not easy to rise, and the energy saving effect is remarkable;

★ The machine tool can be configured with a push tray, and the whole broaching process does not need to press the switch, which is more efficient and convenient;

★ Equipped with chip extractor to facilitate the collection and cleaning of iron filings and reduce labor intensity;

★ Fully automatic centralized lubrication system, each lubrication point can automatically supply oil without manual intervention;