Keyway broach is a special cutting tool used to process semi-circular keyways and flat keyways on mechanical parts, which is divided into two structural types: round cutter body and flat cutter body. The circular tool body is cylindrical with high design accuracy, and the flat tool body adopts a rectangular section with guide bush positioning, which can adapt to the processing needs of different aperture keyways.

The tool forms a keyway through multi-tooth sequential cutting, with a surface roughness of less than Ra1.6μm and a dimensional accuracy of IT7, which is suitable for rectangular, semi-circular, and spline groove processing of carbon steel, alloy steel, stainless steel and other materials. The keyway broach is composed of a leading part, a cutting part and a calibration part, and the calibration part is equipped with a 0.3°~0.5° cutting strip to ensure the machining accuracy. During the processing process, attention should be paid to the adaptability of the length of the guide sleeve, which may affect the processing quality if it is too long or too short. The application of CNC keyway broaching machine enables this tool to achieve high-precision automated machining, and is widely used in the manufacturing of precision parts such as automobile gearbox gears and aero engine components.

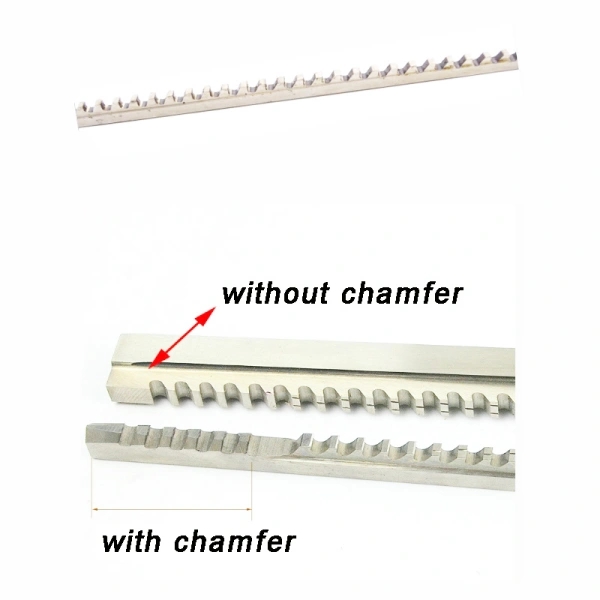

Features of keyway broaches

1. The broaching allowance is large, the number of teeth is large, and the groove depth is large, and it should be drawn more than twice.

2. The broaching surface roughness is large (Ra(2.5~1.25) μm or larger), when the surface roughness is required, a keyway broach with a trimming edge on the side should be used.

3. When the length of the guide sleeve is not enough, it will cause the broach to bend upwards or even break when working.

4. The blade teeth should ensure that the cutting edge belt is wide enough to increase the stability of the broaching process.