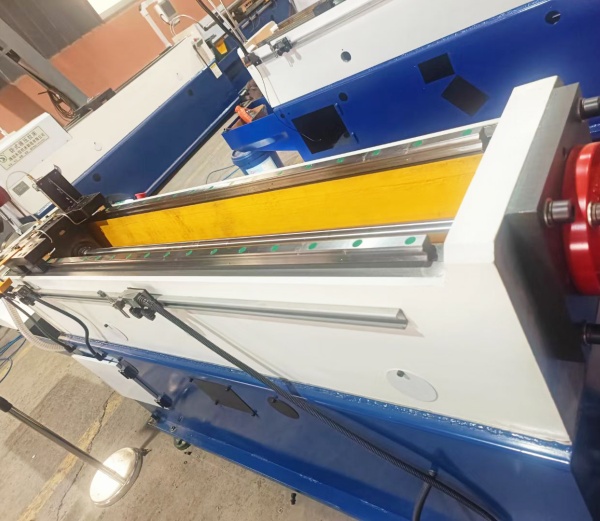

The guide rail broaching machine features a cast bed and high-precision linear guides. It comes standard with a tool rest, waterproof sheet metal, a counter, and a convenient operating lever. It features automatic return stroke and automatic water pump start/stop functions, offering convenient operation and high precision, making it an exceptionally cost-effective option for broaching machines with a cast bed.

Guide Rail Broaching Machine Product Features

★ The bed is cast and annealed for stress relief, resulting in stable precision, excellent rigidity, and minimal vibration during broaching.

★ High-precision linear guides: Horizontal broaching machines feature coaxial cylinder and broaching tool centers. Guideways primarily serve positioning and guidance during broaching, making linear guides the optimal choice. This eliminates the sliding friction of rigid rails and replaces it with rolling friction, significantly extending service life and facilitating maintenance.

★ Integral high-strength base: The base is constructed from high-strength steel plates, bent and welded. After processing, it is integrated with the bed, enhancing overall rigidity and stability.

★ Centralized lubrication system: Each guide rail slider is equipped with a lubrication point, centrally supplied with oil by a lubrication pump, for simple and convenient operation.

★ Dual operation with both a push button and a lever improves ease of use while providing backup for normal production.

★ For keyway broaching, our patented technology enables two different operation modes: one requiring no tool removal and one with automatic tool release upon return, meeting the requirements for broaching keyways of varying specifications with ease, precision, and efficiency.

★ For spline broaching, our company has developed a quick-change chuck that allows for rapid replacement of the chuck to suit different broach specifications, ensuring simple and convenient operation.