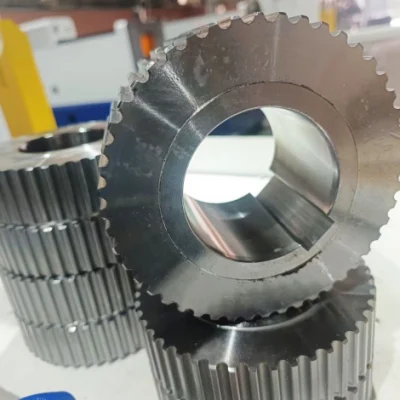

The horizontal machine tool produced by our company has an automatic return function, which is very convenient and efficient when used with automatic chuck. This machine tool can be configured with adjustable height tool holder according to user needs to reduce the labor intensity of operation. It is suitable for processing various hole parts (such as round holes, involute splines, rectangular splines, hexagonal holes, etc.).

We need to use the right cutting method. The cooling system of the hydraulic broaching machine is a system of better quality, and its internal design is relatively exquisite, and once it happens

Then it is very likely that there is an incorrect operation during cutting, resulting in debris entering the cooling system. Before cutting, when pouring the cutting fluid, be careful not to fill the liquid surface, leaving a small part of the space, which is conducive to the subsequent cutting work to allow the chips to be stored in the container. If there is too much debris, pay attention to the cleanliness and hygiene of the hydraulic broaching machine in time.

Our company focuses on the research and development and production of various specifications of vertical and horizontal broaching machines, CNC broaching machines, products are widely used in automobiles, agricultural machinery parts, electric power, textile, hardware and other industries.