Peak Manufacturing Inc. (Denver, Colorado, USA)

Industry: Aerospace & Defense Contract Manufacturing

Challenge: Broaching longitudinal grooves in 300M ultra-high-strength steel landing gear components. The process had to be reliable, documented, and produce a compressive residual surface layer to enhance fatigue life.

Online Discovery: Their process engineer discovered our technical webinar on “Broaching for Aerospace Applications” and registered using his company email.

Initial Contact & Virtual Meeting: The conversations were heavily focused on compliance, material certifications, and process validation (e.g., creating a “broach recipe” for their NADCAP certification). We provided all necessary documentation upfront.

Site Visit: A team from Peak visited to perform a First Article Inspection (FAI) run on our machine. They brought their own material certs and inspection equipment to validate the entire process from start to finish.

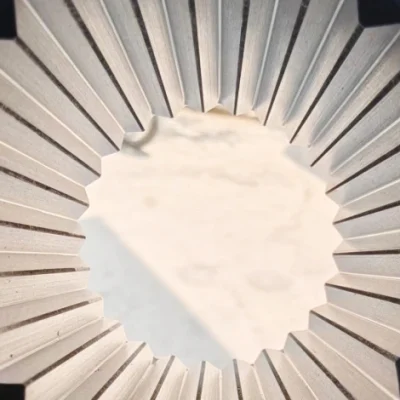

Purchase Decision: They purchased a LC5140B Heavy-Duty Vertical Broach with full data acquisition capabilities to record force, speed, and stroke for every single part, providing the necessary traceability.

Usage & Feedback: “The machine performs flawlessly under the demanding conditions of broaching 300M steel. The data logging feature is invaluable for our quality audits and has streamlined our certification process. The resulting surface integrity and fatigue performance of the components have exceeded our expectations. It’s a vital asset for our long-term contracts.”