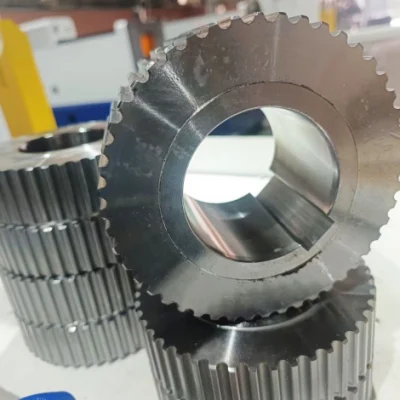

Customer:PT. Mitra Teknik Presisi (Jakarta, Indonesia)

Industry: Auto parts manufacturing

Challenge: Production of internal keyways for transmission gears for local motorcycle manufacturers. Their previous processes using molding machines and EDM were slow, inconsistent, and required highly skilled operators, creating production bottlenecks.

Online discovery: Their production manager discovered that our YouTube channel showcased a vertical broaching machine, creating a perfect keyway in 30 seconds. He downloaded a white paper on “High-volume Keyway Broaching Solutions” from our website and filled out a contact form.

Initial Contact and Virtual Meeting: We held a Zoom call with their engineering team to discuss their specific gear material (SNCM220) and the required keyway size. We shared a CAD simulation of the broaching process for them.

Site visit: Our regional sales engineer visited their factory in Jakarta. He brought the sample tool and demonstrated it on the test gear blank they provided, achieving a perfect finish within tolerances. The main points of discussion were floor space requirements, operator training, and maintenance support.

Purchase Decision: They purchased the LC6120A horizontal hydraulic broaching machine because of its simplicity, sturdiness, and automatic part clamping capabilities. The decisive factor is the significant reduction in cycle time per part.

Use and feedback: “The broaching machine completely eliminated bottlenecks in our gear production. What used to take 15 minutes now takes 30 seconds. The consistency is amazing; For six months, we have zero scrap due to keyway defects. The training was simple and our operators can now confidently manage the machine. It has changed our competitiveness.