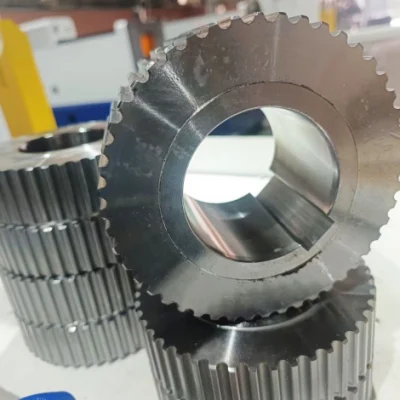

Broaching is a machining operation that uses a tool (or tools) to remove material from a workpiece. The knives have rows of teeth arranged in a spiral or spiral. As the tool moves across the surface, the teeth work together to cut the material away from the workpiece. Let’s take a look at its main benefits for machining parts and components!

1. Fast broaching speed and high efficiency:

This cutting process is relatively fast and efficient, making it ideal for large-scale production. It is a continuous process that can run continuously once it is started.

2. Can manufacture complex shapes:

Broaching is ideal for creating complex shapes that are difficult or impossible to produce with other machining processes. So, if you need to create parts with intricate details, broaching may be the best option.

3. High Accuracy:

This process is known for its high accuracy, so it is often used to manufacture critical components such as gears and engine parts. However, the accuracy of machining can be affected by many factors, such as the type of tool used and the material being machined.

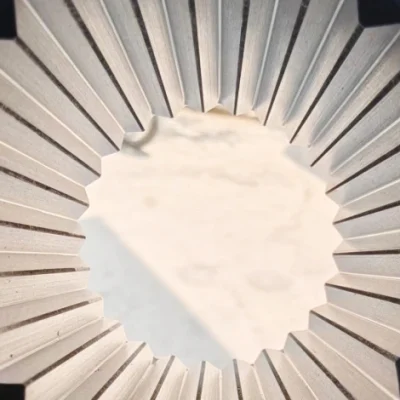

4. Produces a smooth surface finish:

Broaching can also produce a smooth surface finish on the workpiece. Because the teeth on the cutter are arranged in a spiral, this helps minimize vibration during cutting.

5. Versatile Use:

Broaching is a versatile machining process that can be used on a wide range of materials, including metals, plastics, and composites. Moreover, it can be used on ferrous and non-ferrous materials. However, remember to choose the type of tool that matches the material being machined.