Meccanica di Precisione Italiana S.r.l. (Brescia, Italy)

Industry: Luxury Automotive & Motorcycle Components

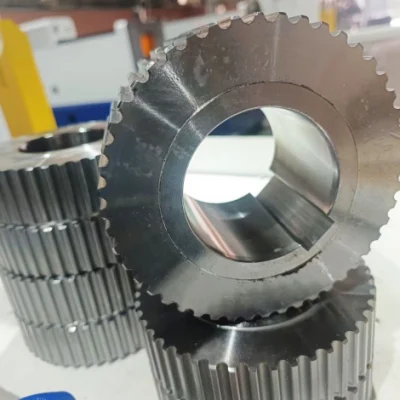

Challenge: Creating flawless external splines on titanium shift forks for high-performance motorcycle gearboxes. Their CNC milling process left tool marks and required extensive finishing, adding cost and time.

Online Discovery: They found us through an Italian machining magazine’s online directory of machine tool suppliers. They were searching for “broaching titanium.”

Initial Contact & Virtual Meeting: We discussed the challenges of broaching titanium (work hardening, tool wear). Our engineering team proposed a specific tool coating (TiAlN) and a customized coolant delivery system to address these issues.

Site Visit: Our application specialist traveled to Italy with a customized broach tool. The live test on a sample titanium blank was successful, achieving the desired mirror-like finish in a single pass, which convinced their master machinist.

Purchase Decision: They ordered a LC6120B Horizontal Broaching Machine with the customized high-pressure coolant system and a set of coated broaches designed specifically for titanium.

Usage & Feedback: “The surface finish is exceptional, straight off the machine. We have completely eliminated the manual polishing step, saving us over 15 minutes per part. The broach tool life in titanium has been better than projected. It has allowed us to scale production for our top-tier clients without compromising on our quality standards.”