Autopartes Hércules S.A. de C.V. (Monterrey, Mexico)

Industry: Tier 1 Automotive Supplier

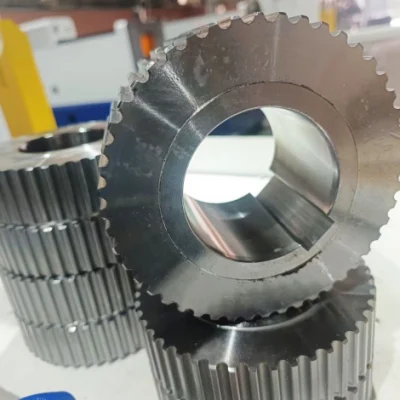

Challenge: High-volume production of serpentine belt pulley grooves (poly-V profiles) on aluminum and cast iron pulleys. Their CNC lathes with grooving tools were too slow and tools wore out quickly, impacting per-part cost.

Online Discovery: Their plant manager found our machines on a B2B platform and requested a quote for a “high-speed pulley grooving solution.”

Initial Contact & Virtual Meeting: We focused on ROI. We calculated the potential cycle time reduction and tooling cost savings compared to their current CNC process, presenting a clear financial case.

Site Visit: We demonstrated a machine dedicated to pulley broaching, highlighting its speed (over 300 parts per hour) and the simplicity of the quick-change fixtures for different pulley models.

Purchase Decision: They ordered a multi station vertical Broaching Machine integrated into a small cell with an automatic loader. This allowed them to broach pulleys as a secondary operation after turning, dramatically increasing throughput.

Usage & Feedback: “The cell runs 24/7 with minimal intervention. Our output for pulleys has increased by 200%, and the cost per part is the lowest it has ever been. The consistency of the groove profile ensures perfect belt alignment and long life. The ROI was achieved in just 11 months.”